In the construction industry, bricks have been a foundational building material for centuries, offering strength, durability, and versatility. However, with the evolving demands for faster construction, enhanced efficiency, and superior quality, traditional brick-making methods are being replaced by cutting-edge technologies. Among these groundbreaking innovations is the Customized Efficient Clay Brick Machine XM4-10 with 100-ton pressure, which is setting new benchmarks in brick manufacturing. In this article, we will explore the features, benefits, and significance of the XM4-10 brick machine, and how it is reshaping the future of the construction industry.

1. The Evolution of Brick Manufacturing

Brick-making has come a long way from its ancient origins. Traditional brick-making processes required significant manual labor, resulting in limited production output and irregular brick shapes. As construction projects become more complex and time-sensitive, there is a growing need for efficient brick manufacturing methods that can produce high-quality bricks in large quantities.

The advent of technology in brick manufacturing has led to the development of modern brick machines that offer improved efficiency, consistency, and environmental sustainability. Among these machines, the Customized Efficient Clay Brick Machine XM4-10 with 100-ton pressure stands out as a pinnacle of innovation.

| Name | XM4-10 100T brick making machine |

| Dimension | 2320*1250*2490mm |

| Shipping cycle | 7-15s |

| Method | Hydraulic pressure |

| Power | 11 KW |

| Rated voltage | 220V,380V,440V |

| Weight | 2000kg |

2.1. Customizable Design

The XM4-10 is a highly customizable brick machine, allowing manufacturers to tailor its features to their precise requirements. The addition of a 100-ton pressure system enables the machine to exert immense force during the brick-making process. This customization results in bricks with enhanced density and strength, making them ideal for projects that demand superior load-bearing capabilities.

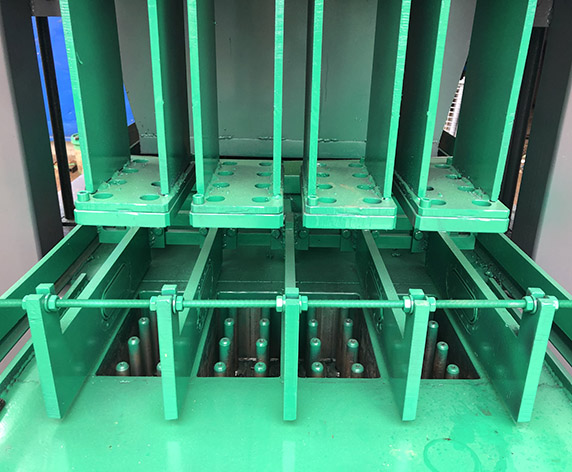

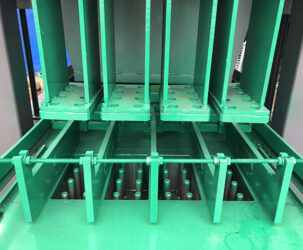

2.2. Quadra-Brick Molding System

At the core of the XM4-10 brick machine lies the quadra-brick molding system, similar to the one found in its predecessor, the XM2-10. This innovative system enables the simultaneous molding of four bricks in a single operation, dramatically increasing production efficiency.

With the 100-ton pressure feature, the quadra-brick molding system ensures that each brick is uniformly compressed, resulting in bricks of unparalleled density and durability. This level of precision and consistency is crucial for constructing robust, long-lasting structures.

2.3. Advanced PLC Control System

The XM4-10 brick machine is equipped with a sophisticated programmable logic controller (PLC) system, allowing for seamless automation and control. The PLC system oversees the entire brick-making process, adjusting the pressure, timing, and other parameters to achieve optimal results.

With the 100-ton pressure customization, the PLC system ensures that the pressure is accurately applied during the molding process, ensuring that each brick attains the desired level of compactness and structural integrity.

3. Advantages of the XM4-10 Customized Efficient Clay Brick Machine

The XM4-10 brick machine offers a myriad of advantages that set it apart as a game-changing solution in the brick manufacturing industry:

3.1. Enhanced Brick Strength and Durability

The 100-ton pressure system in the XM4-10 brick machine results in bricks with exceptional strength and durability. The high-pressure molding process ensures that each brick is compacted uniformly, minimizing the presence of air pockets and weak spots. These bricks can withstand heavy loads and harsh environmental conditions, making them ideal for various construction applications.

3.2. Unmatched Production Efficiency

The quadra-brick molding system, combined with the 100-ton pressure customization, propels the XM4-10 brick machine to new levels of production efficiency. With the ability to produce four bricks simultaneously, construction companies can significantly increase their production output. This enhanced efficiency leads to faster project completion and reduced construction timeframes.

3.3. Improved Brick Aesthetics

Bricks produced by the XM4-10 brick machine with 100-ton pressure exhibit superior aesthetics. The uniform compaction process ensures consistent brick dimensions and surface smoothness, resulting in visually appealing bricks. These bricks enhance the overall appearance of buildings and contribute to the architectural appeal of construction projects.

3.4. Sustainability and Environmental Responsibility

As the construction industry increasingly focuses on sustainability, the XM4-10 brick machine is aligned with the environmental goals of responsible building practices. The automated molding process minimizes waste, while the use of eco-friendly clay as the raw material further supports sustainable construction efforts.

3.5. Versatility and Customizability

The XM4-10 brick machine's versatility allows manufacturers to customize the machine according to their specific requirements. Construction companies can tailor the pressure settings and molding processes to produce bricks suitable for a wide range of applications, from residential housing to large-scale infrastructure projects.

4. The Significance of the XM4-10 Customized Efficient Clay Brick Machine

The XM4-10 brick machine holds immense significance for the construction industry:

4.1. Meeting Growing Demand

With urbanization and population growth driving the demand for construction projects, the need for bricks continues to rise. The XM4-10 brick machine, with its high production efficiency and superior brick quality, ensures a steady supply of bricks to meet this demand. Construction companies that adopt this advanced technology position themselves to excel in competitive markets.

4.2. Elevating Construction Standards

By producing bricks with exceptional strength and durability, the XM4-10 brick machine raises the standards of construction quality. Buildings and infrastructure projects constructed with these high-quality bricks are more resilient, reducing maintenance costs and enhancing long-term sustainability.

4.3. Pioneering Technological Advancements

The XM4-10 brick machine represents the epitome of technological progress in the brick manufacturing industry. By incorporating a 100-ton pressure system and advanced PLC controls, this machine sets the stage for further innovations in construction equipment and automation.

The Customized Efficient Clay Brick Machine XM4-10 with 100-ton pressure is a groundbreaking innovation that redefines brick manufacturing. With its customizable features, quadra-brick molding system, and advanced PLC control, this machine offers unmatched efficiency, enhanced brick quality, and environmental sustainability.

Construction companies that invest in the XM4-10 brick machine position themselves at the forefront of the industry, setting new benchmarks for construction efficiency, strength, and aesthetics. By embracing this cutting-edge technology, manufacturers contribute to sustainable construction practices while elevating the overall quality of buildings and infrastructure projects.

If you are looking for a manufacturer of brick machine in China, you are in the right place. Aiwei Group is one of the most professional manufacturers and suppliers of brick machine.