The construction industry is witnessing a remarkable shift towards automation and intelligent technologies, leading to more efficient and sustainable building practices. In this era of technological advancements, brick factories are embracing innovative solutions to enhance productivity and improve the quality of construction materials. One such groundbreaking innovation is the big production line of the QT10-15 Brick Machine. This state-of-the-art equipment is revolutionizing the brick manufacturing process, offering higher output capacity, improved quality, and significant energy savings. In this article, we will explore the features, advantages, and potential impact of the QT10-15 Brick Machine’s big production line on brick factory upgrades.

1. Full automatic block paver brick block making machine can produce various solid blocks , hollow blocks, pavers and curbstones by changing moulds.

2. Full automatic block paver brick block making machine adopt to hydraulic pressure moulding system , so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density and higher strength.

3. Precise line cutting technology and carburizing treatment technology to prolong mould life and increase precision of the block.

4. Switches will use Japan Omron or France Schneider band, motor will use Siemens or ABB brand.

| Parameters | |

| Name | QT10-15 |

| Size of host machine | 3800*2500*3550 mm |

| Weight of host machine | 11500 kg |

| Forming cycle | 15 seconds |

| Forming method | Hydraulic & Vibration |

| Power of host machine | 51.2 KW |

| Factory size | 4000-5000 ㎡ |

| Products | Hollow bricks, solid bricks, (color) pavers, curbstones, hourdis bricks |

| Raw materials | Concrete, crushed stone, sand, cement, dust, fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

The QT10-15 Brick Machine's big production line is a state-of-the-art system that combines multiple machines to optimize brick production. Let's explore the key components that make up this revolutionary production line:

a. QT10-15 Brick Machine: At the heart of the big production line is the QT10-15 Brick Machine, a fully automated and high-capacity brick-making machine. This machine utilizes hydraulic pressure to compress and mold raw materials into bricks, ensuring consistent quality and precise dimensions.

b. Mixer: The production line incorporates a high-capacity concrete mixer to blend cement, sand, aggregates, and water into a homogenous mixture. This ensures uniformity in the composition and strength of the bricks.

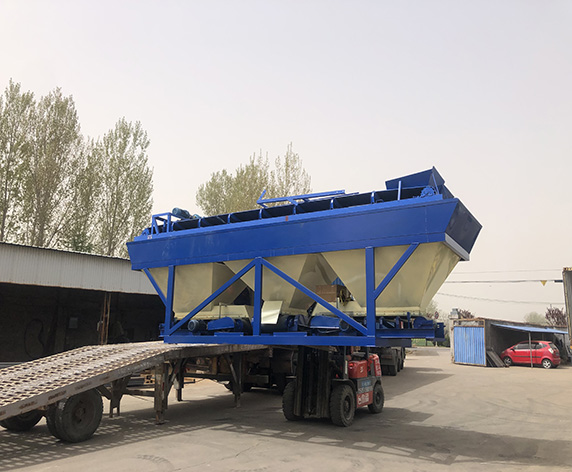

c. Conveyor System: A robust and efficient conveyor system is integrated into the production line to transport raw materials and finished bricks between various machines. This automation reduces manual handling and streamlines the entire brick-making process.

d. Pallet Feeder: The big production line includes a pallet feeder that automatically loads pallets onto the conveyor for brick molding. This eliminates the need for manual pallet handling, enhancing efficiency and reducing labor requirements.

e. Intelligent Control System: The production line's control system is equipped with intelligent automation, powered by advanced algorithms and sensors. This system optimizes various production parameters, such as brick molding pressure, curing time, and conveyor speed, for maximum efficiency and product quality.

a. Enhanced Productivity: The big production line of the QT10-15 Brick Machine significantly improves brick factory productivity. With its high-capacity brick-making machine and automated processes, the production line can produce a large quantity of bricks in a short period, meeting the demands of large-scale construction projects.

b. Consistent Quality: The intelligent control system and precise molding of the QT10-15 Brick Machine ensure uniformity in brick dimensions, density, and strength. This consistency translates into higher-quality bricks, contributing to safer and more durable construction.

c. Labor Optimization: The automation of various processes reduces the need for manual labor, optimizing workforce utilization. Skilled workers can focus on supervisory roles, quality control, and machine maintenance, leading to a more efficient and productive workforce.

d. Resource Efficiency: The big production line optimizes material usage and reduces waste during the brick-making process. This resource efficiency not only lowers costs but also supports sustainable construction practices.

e. Flexibility in Brick Designs: The QT10-15 Brick Machine can produce a wide range of bricks, including standard bricks, interlocking bricks, paving stones, and hollow blocks. This versatility allows brick factories to cater to diverse construction needs and explore innovative brick designs.

a. Streamlining Brick Manufacturing: The big production line of the QT10-15 Brick Machine streamlines the brick manufacturing process, increasing overall factory efficiency. Automation reduces cycle times and minimizes human errors, ensuring the smooth and continuous operation of the production line.

b. Advancing Construction Automation: With the integration of advanced technologies, brick factories can embrace automation in brick manufacturing. This advancement aligns with the industry's transition towards more automated and intelligent construction practices.

c. Fostering Sustainable Practices: The resource efficiency of the big production line supports sustainable brick manufacturing. Brick factories that adopt such technologies demonstrate their commitment to eco-friendly and responsible construction practices.

d. Meeting Growing Construction Demands: With increased productivity and consistent quality, brick factories equipped with the big production line are better equipped to meet the ever-growing demands of the construction industry.

e. Empowering Skilled Workers: Automation does not replace skilled workers but empowers them with more specialized roles. Skilled operators and maintenance technicians are vital to ensuring the smooth operation of the production line and maintaining the highest production standards.

a. Accelerating Construction Timelines: With faster brick production and consistent quality, construction projects can progress more rapidly. The timely availability of high-quality bricks supports faster construction completion, meeting project deadlines more effectively.

b. Advancing Sustainable Construction: The resource optimization and reduced waste in brick manufacturing align with sustainable construction practices. As the industry emphasizes environmental responsibility, adopting such technologies becomes crucial for a greener future.

c. Elevating Global Competitiveness: Brick factories that integrate the big production line of the QT10-15 Brick Machine gain a competitive edge in the global construction market. Improved productivity and quality attract more clients, boosting business growth and market positioning.

d. Supporting Infrastructure Development: The increased capacity of brick production supports infrastructure development, especially in urban areas experiencing rapid growth and development.

The big production line of the QT10-15 Brick Machine marks a significant advancement in brick manufacturing technology. This cutting-edge production line combines automation, intelligent control, and precision engineering to optimize efficiency, productivity, and quality in the production of bricks.

As brick factories embrace this innovative technology, they are poised to revolutionize the construction industry by offering sustainable, high-quality construction materials at an accelerated pace. The big production line of the QT10-15 Brick Machine is not just a tool for brick-making; it is a symbol of progress and a testament to the construction industry’s commitment to embracing advanced technologies for a brighter and more efficient future.

If you are looking for a manufacturer of brick machine in China, you are in the right place. Aiwei Group is one of the most professional manufacturers and suppliers of brick machine.