QT4-24 is a semi automatic vibration concrete cement brick making production line, including mixer, conveyor belt, host machine, block transfer system, controller, trolley, one set of mold. It can produce hollow blocks, solid blocks, paving bricks, hourdis blocks, curbstones etc. Machine can make different kinds of blocks by changing molds.

QT4-24 is a very popular product.

1.QT4-24, the whole frame is made to international standards of manganese steel, hard quality, friction resistance, and service life up to 20 years.

2. QT4-24 has two vibration motors with sufficient power and uses a mode of simultaneous up and down vibration, resulting in a higher density of bricks and better quality bricks.

3.QT4 - 24 has brick platforms, greatly improving handling efficiency and reducing damage during handling.

4.QT4-24 cloth mode can be either electric or manual for better flexibility.

Basic Parameter of QT4-24

| host machine size | 2.15*1.66*2.55m | control box size | 0.83*0.3*0.5m | |

| packing size | 2.3*1.82*2.3m | lifting motor | 3kw | |

| host machine weight | 2000kg | mixer size | 1.26*1.26*1.18m | |

| pallet size | 850*450*20/850*550*20mm | vibration motor(two) | 3kw |

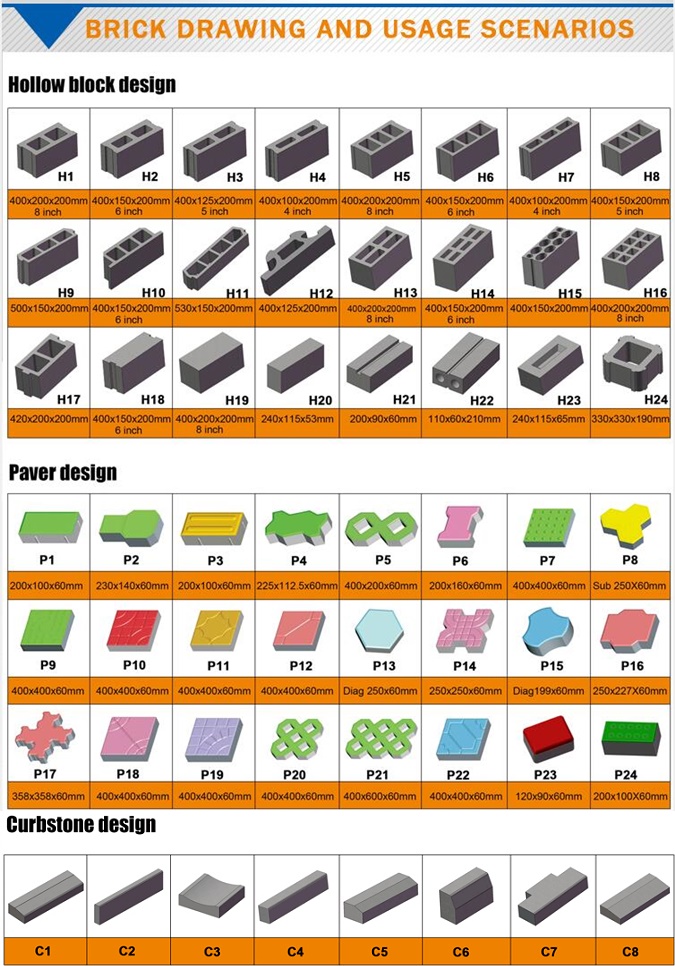

Our machine can make diferent kinds of block by changing molds.

And we also can customized the block mold according to your requirements.

The QT4-24 semi-automatic concrete block making machine represents a valuable investment for brick manufacturers and construction companies alike. Its unique blend of automation and manual control offers numerous benefits, including increased production capacity, consistent block quality, and versatility in design.

By understanding the key features, advantages, and applications of the QT4-24 machine, manufacturers can make informed decisions when upgrading their brick manufacturing processes. This powerful machine is sure to pave the way for sustainable and efficient construction practices, driving the industry towards a more innovative and prosperous future.