The construction industry has witnessed tremendous advancements over the years, with technology playing a pivotal role in revolutionizing traditional processes. One such technological marvel is the XM4-10 Brick Making Machine, which has taken brick manufacturing to a whole new level. Unlike conventional brick-making machines, the XM4-10 has the capability to produce four bricks simultaneously, dramatically improving production efficiency and overall output. In this article, we will delve into the features, benefits, and significance of the XM4-10 brick making machine and explore how it is reshaping the construction landscape.

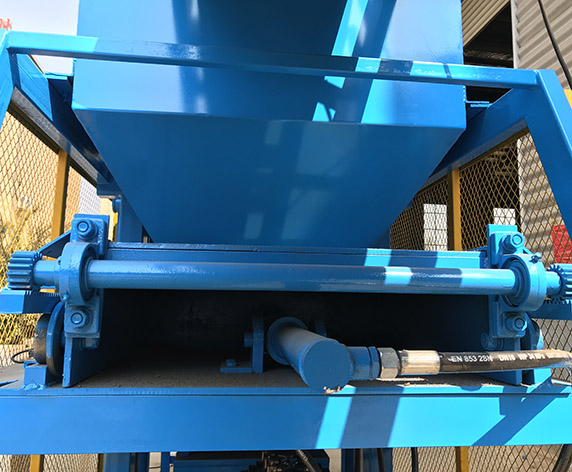

XM4-10 hydraulic clay interlocking brick making machine has been recently developed by my company according to international market demand. It has reasonable structure, excellent performance, very easy to operate, bricks are formed very quickly, it's a very good automatic hydraulic myib interlocking brick machine.

For this XM4-10 hydraulic clay interlocking brick making machine, there is a PLC controller, can feed material, make brick and convey bricks automatically, using hydraulic system, the machine can make clay brick with good quality.

You can make different brick or blocks by changing moulds.

| Name | XM4-10 hydraulic clay cementinterlocking brick making machine |

| Dimension | 2320*1250*2490mm |

| Shipping cycle | 7-15s |

| Method | Hydraulic pressure |

| Power | 7.5 KW |

| Rated voltage | 22V,380V,440V |

| Weight | 1700kg |

1. The Need for Enhanced Brick Production Efficiency

Bricks have been a fundamental building material for centuries, known for their strength, durability, and versatility. With the rapid growth of the global population and urbanization, the demand for bricks has surged significantly. To meet this increasing demand, construction companies are seeking ways to enhance brick production efficiency without compromising on quality.

Conventional brick-making machines can be time-consuming and labor-intensive, resulting in limited production output. Moreover, the environmental impact of brick manufacturing, such as high energy consumption and greenhouse gas emissions, has raised concerns about sustainable practices in the construction industry.

The XM4-10 brick making machine emerges as a solution to these challenges, offering a paradigm shift in brick production efficiency and sustainability.

2. Understanding the XM4-10 Brick Making Machine

The XM4-10 brick making machine is a cutting-edge innovation that redefines the brick manufacturing process. Designed and engineered by industry experts, this machine is equipped with advanced technology and intelligent automation to produce four bricks simultaneously in a single cycle. This unprecedented capability significantly enhances production efficiency, reducing labor requirements, and increasing overall output.

2.1. Quadra-Brick Molding System

At the heart of the XM4-10 brick making machine lies the quadra-brick molding system. This innovative system enables the simultaneous molding of four bricks in a single operation. The machine precisely shapes the raw material - typically clay or other suitable materials - into four identical bricks with consistent dimensions and properties.

The quadra-brick molding system not only increases efficiency but also ensures uniformity in brick size, shape, and density. This level of consistency is crucial in construction, as it facilitates smooth and stable construction processes, resulting in more durable and aesthetically pleasing structures.

2.2. High-Capacity Mixing System

To ensure the production of high-quality bricks, the XM4-10 brick making machine incorporates a high-capacity mixing system. This system efficiently blends the raw material with water and other additives to create a homogenous clay mixture. Proper mixing is essential to achieve bricks with optimal strength and durability.

The high-capacity mixing system allows for greater flexibility in adjusting the clay composition, making it possible to adapt the production process to meet specific project requirements.

2.3. PLC Control System

The XM4-10 brick making machine is equipped with a sophisticated programmable logic controller (PLC) system, which acts as the brain of the operation. The PLC system oversees the entire production process, coordinating the different components and ensuring seamless operation.

With the PLC control system, manufacturers can set precise parameters, monitor the production status, and diagnose any potential issues. This automation minimizes the risk of errors and optimizes production efficiency, reducing the reliance on manual labor.

3. Advantages of the XM4-10 Brick Making Machine

The XM4-10 brick making machine offers a plethora of advantages that make it a game-changer in the brick manufacturing industry:

3.1. Quadruple Production Output

The most significant advantage of the XM4-10 brick making machine is its ability to produce four bricks simultaneously. Compared to conventional brick-making machines that produce one brick at a time, this quadruples the production output. As a result, construction companies can meet higher demand and complete projects in a shorter timeframe.

3.2. Unmatched Efficiency

The quadra-brick molding system, coupled with the high-capacity mixing system and PLC control, creates an exceptionally efficient brick manufacturing process. The machine streamlines the entire production cycle, reducing manual intervention and optimizing energy usage. This efficiency translates into cost savings and improved productivity.

3.3. Superior Brick Quality

Consistency is paramount when it comes to brick quality. The XM4-10 brick making machine ensures that all four bricks produced in each cycle are identical in size, shape, and strength. This consistency results in bricks with enhanced structural integrity and visual appeal. The superior brick quality reflects positively on the construction projects, contributing to their long-term durability and aesthetics.

3.4. Labor-Saving Solution

The XM4-10 brick making machine significantly reduces the need for manual labor. With its automated processes and quadra-brick molding system, a single machine can produce a substantial number of bricks with minimal human intervention. This labor-saving aspect not only reduces operational costs but also addresses the challenges of finding skilled labor for brick manufacturing.

3.5. Environmentally Conscious Production

The XM4-10 brick making machine adopts an environmentally conscious approach to brick production. Its high efficiency and energy optimization lead to reduced energy consumption, minimizing greenhouse gas emissions. Additionally, the use of sustainable materials, such as clay, further contributes to eco-friendly construction practices.

4. The Significance of the XM4-10 Brick Making Machine

The XM4-10 brick making machine holds immense significance for the construction industry:

4.1. Meeting Growing Demand

With rapid urbanization and population growth, the demand for bricks continues to surge. The XM4-10 brick making machine addresses this demand by revolutionizing brick production efficiency. By quadrupling production output, construction companies can keep up with the ever-increasing demand for bricks and stay ahead in competitive markets.

4.2. Advancing Sustainable Construction

Sustainability is a critical aspect of modern construction practices. The XM4-10 brick making machine's eco-friendly features, including energy efficiency and the use of sustainable materials, align with the industry's efforts to reduce the environmental impact of construction projects. Embracing this technology demonstrates a commitment to sustainable and responsible building practices.

4.3. Driving Technological Progress

The XM4-10 brick making machine is a testament to the potential of cutting-edge technology in transforming traditional industries. Its quadra-brick molding system and PLC control represent innovations that redefine brick manufacturing. As the industry witnesses the benefits of such technological advancements, it encourages further research and development in brick-making technology.

The XM4-10 Brick Making Machine has ushered in a new era of brick manufacturing, offering unmatched efficiency, superior quality, and eco-conscious practices. With its ability to produce four bricks at once, this machine has become a cornerstone of efficient and sustainable construction. Construction companies that embrace the XM4-10 brick making machine position themselves at the forefront of technological progress, ensuring success, and resilience in the ever-evolving construction landscape.

If you are looking for a manufacturer of brick making machine in China, you are in the right place. Aiwei Group is one of the most professional manufacturers and suppliers of brick making machine.